Ever wondered how industries power tools, maintain cleanrooms, or ensure safe gas transport? The answer lies in three critical systems: compressed air, vacuum, and inert gas. Each serves unique purposes, but choosing the right system—and the right piping—can transform efficiency. This beginner’s guide explores their key differences, applications, and why Quickair from Canares Automation Pvt Ltd delivers India’s best modular piping for all three.

What Are These Systems?

Let’s define each system:

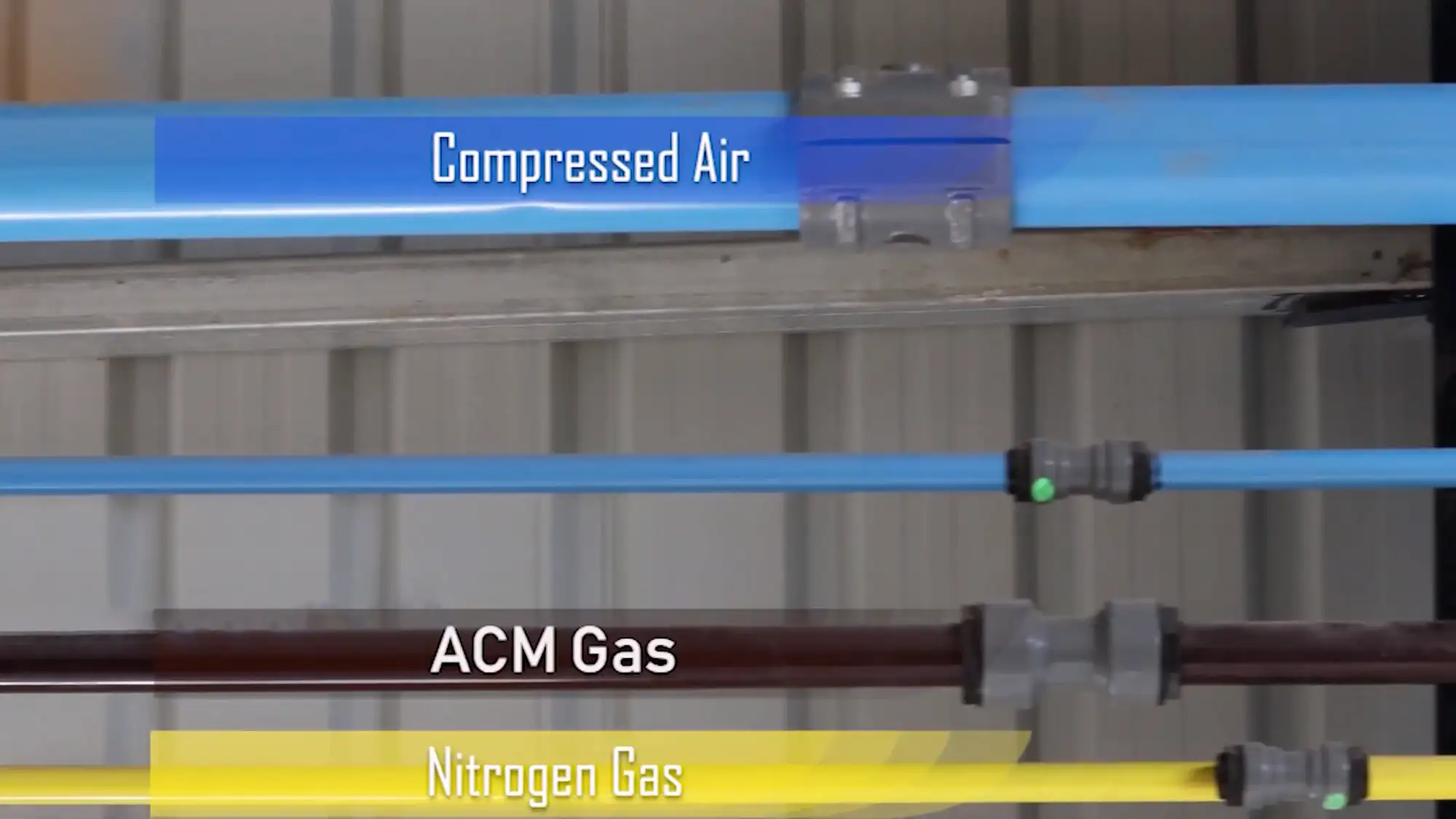

- Compressed Air Systems: Deliver high-pressure air to power tools, machinery, or processes, like pneumatic drills in factories.

- Vacuum Systems: Create low-pressure environments to remove air or particles, such as in packaging or HVAC systems.

- Inert Gas Systems: Transport non-reactive gases (e.g., nitrogen, argon) for safety or contamination control, like in pharmaceuticals.

Quickair, from Canares Automation Pvt Ltd, is India’s only manufacturer of modular piping systems for these applications. Their patented technology ensures efficiency and reliability. See a Quickair system in action:

Key Differences Between the Systems

These systems differ in purpose, pressure, materials, and costs:

1. Purpose and Function

- Compressed Air: Powers equipment with pressurized air, driving tools like spray guns or conveyors.

- Vacuum: Removes air for suction or low-pressure zones, essential for packaging or scientific research.

- Inert Gas: Transports non-reactive gases for safety (e.g., preventing explosions) or product purity.

2. Pressure Requirements

- Compressed Air: Operates at high pressure (6–10 bar) for mechanical work. Quickair’s leak-free pipes cut energy loss by 30%.

- Vacuum: Maintains low pressure (0.1–0.9 bar) for suction. Precision fittings prevent air ingress.

- Inert Gas: Uses controlled pressure (varies) for safe, steady flow without contamination.

3. Materials and Piping Needs

- Compressed Air: Needs durable, corrosion-resistant pipes (e.g., aluminum) for high pressure. Quickair’s anodized aluminum excels.

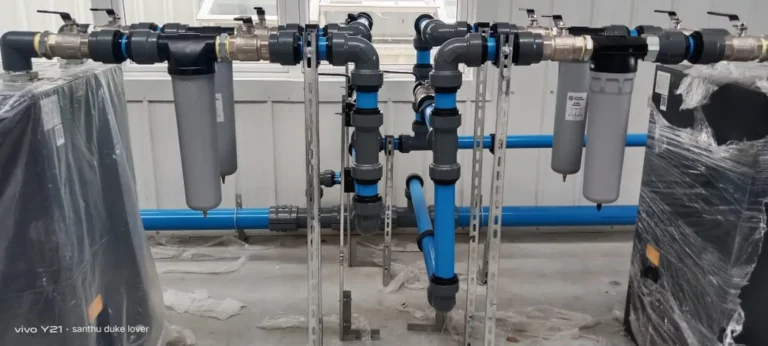

- Vacuum: Requires airtight, lightweight pipes for suction. Quickair’s push-fit technology ensures zero leaks.

- Inert Gas: Demands non-reactive, clean pipes to avoid contamination. Quickair guarantees purity.

4. Energy and Cost Considerations

- Compressed Air: High energy use; leaks waste 20–30% of energy. Quickair’s airflow optimization saves 25% on bills.

- Vacuum: Moderate energy needs, but airtight seals are key. Quickair reduces maintenance costs.

- Inert Gas: Lower energy use but higher gas costs. Quickair’s modular design cuts installation expenses.

Applications Across Industries

Each system serves distinct industries:

- Compressed Air: Powers automotive assembly, textile machinery, and food packaging. A Quickair system in a Maharashtra factory saved 20% on energy costs.

- Vacuum: Used in pharmaceutical packaging, electronics, and HVAC for air removal.

- Inert Gas: Critical for welding (argon), pharmaceutical cleanrooms (nitrogen), and food preservation (CO2).

Quickair’s modular piping, backed by Canares’ quality standards, meets these diverse needs with reliable components.

Why Quickair Excels for All Three Systems

The right piping is critical. Canares Automation Pvt Ltd’s Quickair sets the standard:

- Universal Compatibility: Supports compressed air, vacuum, and inert gas, with 20% lighter pipes for vacuum than competitors.

- Patented Technology: Push-fit systems enable 50% faster installation than traditional piping.

- Made in India: Unlike imported systems, Quickair’s local manufacturing ensures faster delivery and support.

- Cost Efficiency: Reduces maintenance costs by 15% compared to steel pipes.

- Expert Support: Canares’ design and installation guidance guarantees performance.

Common Questions for Beginners

New to these systems? Here’s what beginners ask:

- Which system do I need? Compressed air for power, vacuum for suction, inert gas for safety. Canares can guide you.

- Are modular pipes worth it? Yes! Quickair saves 20–30% on energy and installation costs.

- What challenges do these systems face? Compressed air uses more energy, vacuum needs tight seals, and inert gas requires purity. Quickair’s leak-free, non-reactive pipes address these.

- How does Quickair compare? Quickair’s patented technology and local expertise outperform generic systems.

How to Choose the Right System

Ready to get started? Follow these steps:

- Identify Your Goal: Power tools? Remove air? Ensure safety?

- Assess Requirements: Evaluate pressure, flow, and contamination risks.

- Choose Piping: Select Quickair’s aluminum modular systems for efficiency.

- Consult Experts: Partner with Canares for custom designs.

- Monitor and Maintain: Quickair’s low-maintenance systems ensure longevity.

Conclusion

Compressed air, vacuum, and inert gas systems each drive industry success, but their differences demand the right piping. Don’t let outdated systems slow you down—Quickair from Canares Automation Pvt Ltd offers India’s most innovative modular piping, delivering fast installation, energy savings, and reliability. Visit canares.com today to transform your operations with Quickair!