5 Steps to Designing an Efficient Compressed Air System

Imagine your facility’s energy bill spiking due to a hidden leak in your compressed air system, wasting 30% of your air—and thousands in costs. This is a reality for many industries, from automotive to pharmaceuticals, where compressed air powers critical processes. An efficient system can save up to 30% on energy and boost productivity. At Canares Automation, our Quickair™ modular piping solutions deliver leak-free, sustainable performance. Follow these five steps to design a compressed air system that optimizes efficiency and cuts costs.

1. Assess Your Air Demand

Begin by mapping your facility’s compressed air needs. Identify equipment—such as pneumatic tools in automotive plants or packaging systems in pharmaceuticals—and record their pressure (PSI) and flow (CFM) requirements. Create a demand profile to capture peak and average usage, ensuring your system matches needs without oversizing, which wastes energy. For example, an electronics manufacturer might need variable air for circuit assembly. Use demand profiling software to streamline this process, and factor in future expansion to avoid redesigns. This step lays the foundation for an efficient system.

2. Select the Right Compressor and Room Setup

Choosing the right compressor and designing its environment are critical for efficiency. Opt for a Variable Speed Drive (VSD) compressor, which adjusts output to demand, saving up to 35% on energy (Fluid-Aire Dynamics). Fixed-speed models suit smaller, stable operations. Match capacity to your demand profile to handle peak loads efficiently. Include dryers and filters to remove moisture and contaminants, vital for pharmaceutical air quality. Equally important is the compressor room:

- Ventilation: Ensure clean, cool intake air to prevent overheating.

- Foundation: Use stable mounts to reduce vibration.

- Noise Control: Install soundproofing for worker safety.

A well-designed room enhances compressor longevity, reducing energy waste.

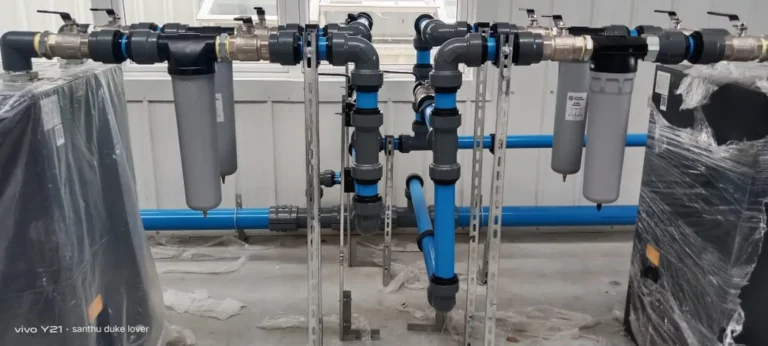

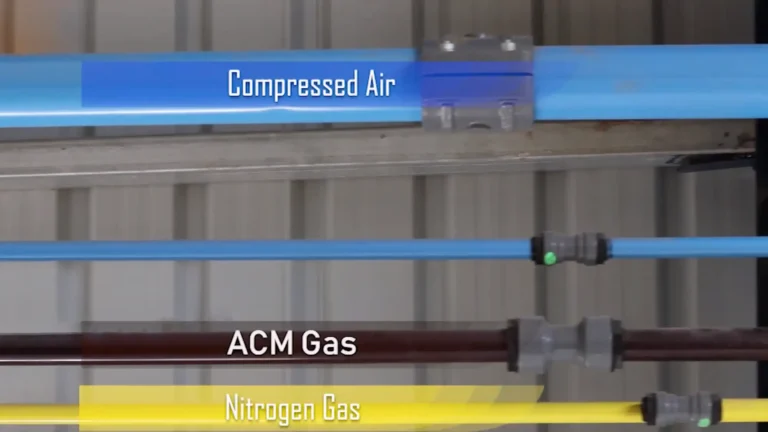

3. Optimize Your Distribution System

- Material: Use corrosion-resistant aluminum piping, like Quickair™, for durability and leak-free performance. Its push-fit design simplifies installation.

- Layout: Implement a ring main layout for consistent pressure, avoiding long runs that increase losses.

- Sizing: Balance pipe diameter—oversized pipes waste energy, undersized ones cause drops. Every 1 bar drop raises power use by 6-7% (FluidFlow).

- Leak Prevention: Select fittings that ensure tight seals, like Quickair™’s modular connectors.

- Pressure Regulation: Install regulators to maintain optimal pressure at each point of use.

For example, a pharmaceutical plant using Quickair™ minimizes pressure drops, ensuring reliable airflow.

4. Implement Smart Monitoring

Smart monitoring maximizes efficiency by adapting to real-time needs. Integrate:

- IoT Sensors: Use pressure transducers and flow meters to detect leaks or inefficiencies instantly. For instance, an automotive facility can identify a faulty valve before it escalates.

- Smart Controls: Deploy systems that adjust compressor output dynamically, preventing over-pressurization and saving up to 10% on energy.

- Data Analytics: Analyze sensor data to spot trends, such as recurring pressure drops, and optimize performance.

These technologies align with Canares’ sustainability focus, enabling precise control. An electronics firm, for example, could use IoT monitoring to maintain consistent air for delicate processes, reducing waste.

5. Sustain Performance Through Maintenance and Compliance

Long-term efficiency requires proactive maintenance and adherence to standards. Inefficient systems can lose 25% of air to leaks, especially in older piping (Air Piping Solutions). Key actions:

- Leak Inspections: Conduct quarterly checks using ultrasonic detectors to catch leaks early, saving thousands annually.

- Air Quality: Monitor for contaminants, critical in pharmaceuticals to meet ISO 8573 standards (e.g., Class 1 for oil-free air).

- Compressor Upkeep: Follow manufacturer schedules for filter changes and oil checks to maintain efficiency.

- Compliance: Ensure systems meet industry regulations, such as OSHA noise limits or FDA air purity requirements.

Quickair™’s durable pipes reduce maintenance needs, ensuring reliability. A maintenance log and spare parts inventory minimize downtime.

Conclusion

An efficient compressed air system is a strategic investment, cutting energy costs by up to 30% and enhancing reliability. By assessing demand, selecting the right compressor and room setup, optimizing distribution with Quickair™, implementing smart monitoring, and sustaining performance, businesses achieve operational excellence. For example, an electronics firm using Quickair™ reduced energy costs by 25% through leak-free piping and IoT controls. Canares Automation is committed to sustainable solutions for industries like automotive and pharmaceuticals.

Ready to transform your compressed air system? Contact Canares to explore Quickair™ modular piping and design an efficient, future-proof system today.

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.