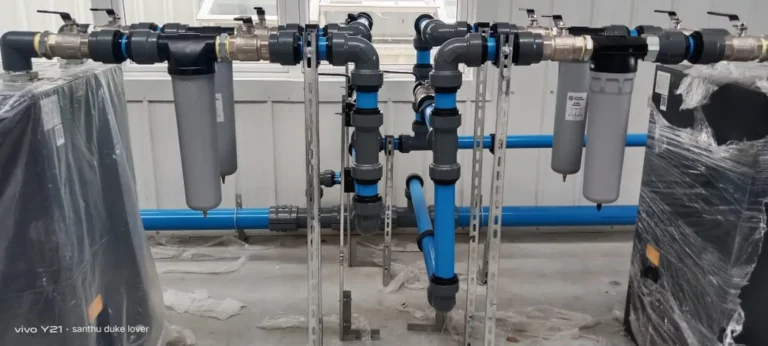

Did you know the wrong piping material could cost your business thousands in energy losses or repairs? In modular piping systems for compressed air, vacuum, and inert gases, material choice drives efficiency, durability, and savings. This beginner’s guide explains how materials like aluminum, steel, and PVC perform and why Quickair from Canares Automation Pvt Ltd leads with innovative aluminum solutions. See Quickair in action:

Why Material Choice Matters

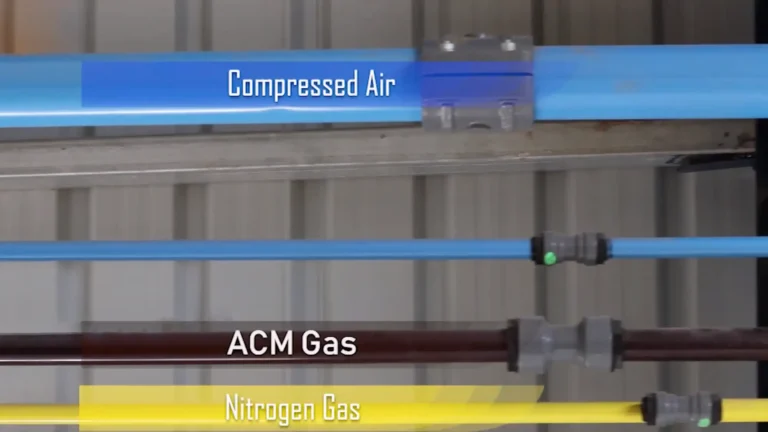

Modular piping systems power industries like manufacturing, pharmaceuticals, and food processing with compressed air, vacuum, or inert gases. The material—aluminum, steel, PVC, or copper—affects performance under pressure, corrosion, or temperature. Choosing wisely ensures efficiency and longevity. Quickair, India’s only modular piping manufacturer, uses anodized aluminum for unmatched results.

Key Materials and Their Impact

Here’s how common materials compare:

1. Aluminum

- Performance: Lightweight, corrosion-resistant, supports pressures up to 16 bar, and reduces pressure drops by 25%.

- Applications: Perfect for compressed air, vacuum, and inert gas. Quickair’s aluminum shines in factories and cleanrooms.

- Pros: Leak-free, long lifespan (20+ years), recyclable.

- Cons: Higher upfront cost than PVC.

2. Steel

- Performance: Strong for high pressure but rusts, causing leaks and 30% energy loss.

- Applications: Heavy industries, less suited for vacuum or inert gas.

- Pros: High strength, widely available.

- Cons: Heavy, rust-prone, short lifespan (5–10 years).

3. PVC

- Performance: Cheap, limited to 10 bar, cracks under high pressure or heat (>60°C).

- Applications: Low-pressure vacuum or inert gas in non-critical settings.

- Pros: Low cost, easy installation.

- Cons: Brittle, not durable, may leach chemicals.

4. Copper

- Performance: Corrosion-resistant, reliable for inert gas but costly.

- Applications: Pharmaceuticals for nitrogen or argon.

- Pros: Long lifespan, clean for sensitive uses.

- Cons: Expensive, labor-intensive installation.

Performance Metrics Affected by Material

Materials impact key metrics:

1. Energy Efficiency

Quickair’s aluminum minimizes leaks, saving 20–30% on energy costs in compressed air systems. Steel’s rust increases friction, wasting energy.

2. Durability and Maintenance

Aluminum and copper last decades with minimal upkeep. Steel needs frequent repairs, and PVC requires replacement every 5–7 years.

3. Installation Speed and Cost

Quickair’s aluminum push-fit systems install 50% faster than steel or copper, cutting labor costs. A Delhi factory saved ₹2 lakh by installing Quickair in 2 days instead of 5.

4. Safety and Purity

Inert gas systems need non-reactive materials like Quickair’s aluminum to ensure purity in cleanrooms, unlike steel’s rust risks.

Why Quickair’s Aluminum Stands Out

Quickair by Canares Automation Pvt Ltd excels:

- Optimized Performance: 20% lighter than steel, leak-free for compressed air, vacuum, and inert gas.

- Patented Technology: Push-fit systems reduce installation costs by 30%.

- Made in India: Unlike imported systems, Quickair cuts lead times by 40%.

- Cost Efficiency: Saves 15% on maintenance vs. steel.

- Expert Guidance: Canares ensures tailored, high-performance systems.

Common Questions About Piping Materials

Beginner concerns answered:

- Which material is best? Aluminum, like Quickair’s, balances cost, durability, and efficiency.

- Is aluminum worth it? Yes, saving 20–30% on energy and installation.

- What challenges do materials face? Steel rusts, PVC cracks, copper’s costly. Quickair’s aluminum avoids these.

- Are materials sustainable? Quickair’s aluminum is 100% recyclable, unlike PVC’s environmental risks.

- How does Quickair compare? Patented, locally made systems outperform generic pipes.

How to Choose the Right Material

Select your piping material with these steps:

- Define Your System: Compressed air, vacuum, or inert gas? Check pressure needs.

- Evaluate Conditions: Assess corrosion, temperature, load. Aluminum suits most.

- Prioritize Efficiency: Choose Quickair’s aluminum for savings.

- Consult Experts: Partner with Canares for solutions.

- Plan for Longevity: Invest in Quickair’s durable pipes.

Conclusion

Material choice shapes modular piping performance, from energy savings to durability. Don’t let outdated materials hold you back—act now to transform your operations with Quickair from Canares Automation Pvt Ltd. India’s leading aluminum modular piping delivers fast installation, cost efficiency, and reliability. Visit canares.com today to get started!